Fishing Reel Bearings

What Makes Your Reel Go Round!

Fishing reel bearings are located throughout both spinning and baitcasting reels wherever there are components that must spin/rotate. The spool, pinion gear and under drag washers, They serve to facilitate the rotation of gears, knobs, spools and even level wind devices. Without them, the term "smooth" would not be in our fishing reel vocabulary. Fishing would be more of an ordeal than the enjoyable experience it is today.

We've all heard a million times that "the more ball bearings a reel has the better the reel". Is this always true? What about ceramic bearings or these ceramic hybrid bearings we hear about? What do they offer in improved reel function and durability? Read on and let's see if we can answer these questions.

Components Of Fishing Reel Bearings

The small ball bearings in fishing reels serve the same purpose in baitcasting or spinning reels as they do in any other mechanical device - reduction of friction between moving parts. So they fall into the classification of "anti-friction bearings". Without them life would be far more difficult. Any time two objects come in contact while moving across one another friction is generated and the resulting force is resistance against the motion. Motion is slowed or stopped all together.

You will find that most reel companies place ball bearings at several locations within a reel. Where there are rotating parts in contact with one another you can find ball bearings. The number can range from three to as many as eleven. There are spool, clutch, knob and frame bearings for example.

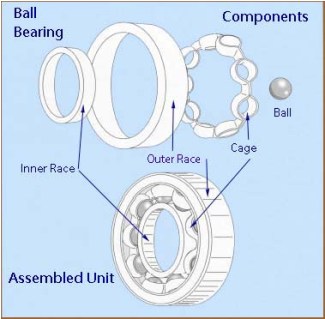

Most reels today, particularly high grade reels whether spinning or baitcasting, use precision, stainless steel "radial ball bearings". However, more and more solid and ceramic coated bearings are making the scene. The radial ball bearing units we're talking about consist of an inner and outer ring within which is a cage, made of plastic or steel, containing a number of precision balls. The cage functions to keep the balls separated. These fishing reel bearing units are usually of deep-groove construction which accommodates both radial and axial loads common with fishing reels.

The diagrams above and to the right show the individual parts of a ball bearing unit and the "assembled" unit. The unit itself is also referred to as a ball bearing or Conrad bearing. Why? It's really not important but if you must know he is the guy that invented it. The balls are placed inside the tracks of the outer and inner races and evenly distributed. The cage is then positioned over the balls to keep them separated and evenly distributed.

The four parts of fishing reel bearings are:

- Races are simply rings of stainless steel that have been formed, hardened and finished by grinding to a very smooth almost mirror like surface. A unit includes both an inner and outer race.

- Cages look similar to a chain, at least to me. They are either plastic or stainless steel. They consist of linked "collars" within which the individual balls are located. In these open end collars they are kept separated and equidistant from one another.

- Balls Stainless Balls are formed from a length of wire by cold heading. This is a process that uses pressure rather than heat. After this they are machined smooth by several sequential steps and heat treated to attain necessary hardness.Ceramic material in fishing reel bearings is usually limited to the rolling elements, the balls. Ceramic balls placed within stainless steel races and cages are "hybrid ceramic bearings".

- Shields come to play in fishing reel ball bearings when there is a need/desire to keep lubricates in the bearing and dirt out. These can be either permanent or removable. The latter makes cleaning or adding new lubrication a little more difficult.

What Constitutes Quality Fishing Reel Bearings?

The "rolling action" of fishing reel bearings or ball bearings in any other device, which is what defines their quality, depends on the roundness, precision, and hardness of its components. High quality ball bearings like those found in upper end reels have extremely close tolerances as defined by ABEC standards. This translates into very little play and almost friction free rotation. Less expensive, low end reels may have bearings made of chrome plated steel, chrome steel or other inferior materials. The function and durability of these bearings falls far short of "precision" stainless steel or ceramic ball bearings.

Stainless Steel Or Ceramic?

Fishing Reel Bearings- Stainless Steel

- Dominant ball bearing found in today's fishing reels.

- Relatively inexpensive to produce.

- Surface wear is not uncommon even when lubricated.

- Shorter life span than ceramic balls.

- Required heat treatment to strengthen the steel unfortunately weakens their resistance to corrosion. Especially important in saltwater environments.

Fishing Reel Bearings - Ceramic

- Expensive to produce.

- Can be solid or a coating on stainless steel balls.

- If solid ceramic they're lighter than stainless steel by as much as 60%. This means lighter weight reels since the balls make up 50-75% of a bearings weight.

- The wear rate of ceramic ball bearings is significantly less than stainless steel especially when lubricated. This feature contributes to a life expectancy as much as five times that of stainless.

- More corrosion resistant than stainless steel.

- Generate less destructive heat.

- An extremely smooth surface and uniform size is attainable which contributes to much less friction and slip.

- Lower levels of vibration and higher speeds than with stainless.

- In fishing reels, ceramic ball bearings are usually "ceramic hybrid bearings", which means they consist of ceramic balls enclosed in a stainless steel (sometimes plastic) cage enclosed in an inner and outer stainless steel race unit.

With Ball Bearings You Get What You Pay For

If you never clean or repair your reels. If you don't fine tune them by replacing the stock bearings that come in them with "upgraded bearings", you could probably skip this section of the page. You'll find more about bearing quality and "upgrading bearings" in future articles dealing with reel maintenance (yet to be constructed) on this site.

ABEC Rating What Is It?

As with so many other industries, that part of the ball bearing industry that concentrates on producing "precision ball bearings seeks to adhere to different levels of domestic and internationally established quality ratings. With U.S domestic ball bearings it's the Annular Bearing Engineers Committee, or shorter and easier to say, the ABEC. This committee is part of the larger American Bearing Manufacturers Association or ABMA. The standards it sets closely mimic those of the ISO, the International Standards Organization and ANSI, and the American National Standards Institute.

If you don't what these organizations are don't waste a minute learning about them. Just know that they exist, at least theoretically, too set standards for industry and business (world wide) that supposedly insure better manufacturing practices and better finished products. The degree of success or failure of these "independent" standard setting entities in accomplishing this is debatable, in my humble opinion, and could be the subject for another entire web site.

Nevertheless, in this article on fishing reel bearings, at least relative to ball bearing tolerances, we're proceeding under the assumption the ABEC 1 (lowest) through ABEC 9 (highest) standards, which really only deal with "tolerances", are reliable indicators of "dimensional precision".

The higher the rating, the closer he ball is to dimensional perfection. Not a bad thing as this contributes to a more true rotation and higher speed. Note, however, that this is but one ingredient in the quality ball bearing recipe. Surface finish, race curvature, lubrication, material, corrosion resistance and number of balls also affect quality.

More Than You Want To Know?

If you're into just fishing and not maintenance and repair, just focus on the number of ball bearings in a reel and the material from which they are made. A manufacturer will include this in its reel description. That's all you need to know. Keep in mind, the number of fishing reel bearings does contribute to whether a reel performs poorly or if it functions at a high level.

CAVEAT - Remember, six poor quality fishing reel bearings may perform poorer than four quality bearings.

The table below will give you a sampling of the ball bearing differences between some popular reel manufacturers. Where able to do so, I've tried to identify what the specific material is when trademark names are used to describe bearings. I've also included 2010 prices so you might get a feel for the relationship between reel price and the number and type of ball bearings in reels.

Baitcast Reels| Brand | Reel | Bearings | Type | Price | |

|---|---|---|---|---|---|

| Abu | REVO Premier | 9+1 HCPR | Stainless | $279.99 | |

| Abu | REVO STX | 10+1 HCPR | Stainless | $199.99 | |

| Abu | REVO S | 8+1 | Stainless | $129.99 | |

| Abu | REVO Toro™ | 6+1 HCPR | Stainless | $269.99 | |

| Daiwa | Steez™ | 11+1 CRBB | Stainless | $479.99 | |

| Daiwa | Zillion™ | 6+1 CRBB | Stainless | $269.99 | |

| Daiwa | Megaforce® | 5+2 | Stainless | $ 69.00 | |

| Shimano | Core™ 50 | 8 S A-RB | Stainless | $369.99 | |

| Shimano | Curado E, 200E7 | 5+1 S A-RB | Stainless, Shielded | $179.99 | |

| Shimano | Citica® E | 3+1 | Stainless, Shielded | $119.19 | |

| Pflueger | Patriarch ™ | 10+1 | Stainless | $199.99 | |

| Pflueger | Cetina® | 9+1 | Stainless, Shielded | $ 89.99 | |

| Quantum | KVd Tour | 10+1 | Polymer-stainless Hybrid | $299.99 | |

| Quantum | Energy® PT | 8+1 | Polymer-stainless Hybrid | $189.99 |

Some Helpful Trademark Name Definitions

CRBB Bearings (Corrosion Resistant Ball Bearings) are Daiwa’s specially treated, sealed, stainless steel and are advertised to last up to 12 times longer than standard stainless steel bearings, especially beneficial in corrosive saltwater environment.

HPCR Bearings (High Performance Corrosion Resistant) are Abu Garcia's rust resistant, shielded, stainless steel ball bearings. Advertised as a steel that is not "specially treated" after manufacture but is instead a specific type of rust resistant steel. Allegedly, this steel handles more stress, runs better dry and at higher RPM, and if ever contaminated, will continue to run better than a standard bearing.

A-RB Bearingsare stainless steel, no shield (open), ball bearings that have been through the A-RB treatment process which makes them, allegedly, at least 10 times more corrosion resistant than standard stainless steel ball bearings. They are also advertised as being able to rotate at a higher speed due to the open design and low viscosity lubrication.

Return To Bass Fishing Reels From Fishing Reel Bearings